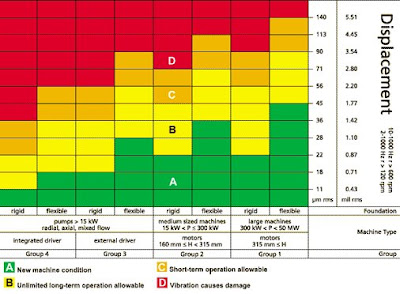

Use the chart below combined with. Your equipment. VIBRATION SEVERITY PER ISO 10816 Vibration Velocity Vrms Machine Class I Class II Class III Class IV. ISO 10816-1:1995 Mechanical vibration -- Evaluation of machine vibration by measurements on non-rotating parts -- Part 1. Replaces ISO 2372 and ISO 3945. Craig Shaw Gardner Lost Boys Ebook Download on this page.

Clarification on ISO 10816-6 vibration standards - Reliability Magazine® Message Boards Clarification on ISO 10816-6 vibration standards Author Topic: Clarification on ISO 10816-6 vibration standards vasanth Member posted 02:26 AM I recently got a copy of the vibration standard ISO 10816-Part 6 ( reciprocating machines with power ratings above 100 kw ). On page 6 Table a.1 there is a table for vibration classification numbers and guide values for reciprocating machines. The third column of this table is for Machine vibration classification number. Unfortunately the standard doesn't define what these classification stands for? It just mentions that ' for example Many industrial and marine diesel engines may be classified in either classification number 5,6 or 7 '.

Which is really vague. Does any one have any clarification on this? Also from what I understand that these limits are only for the reciprocating machine and not for the connected machinery namely alternators or Propulsion systems etc. Any opinions on this. Thankx in advance. Vasanth IP: OLI Member posted 10:04 AM I think, and may be wrong that the makers of the machines are supposed to supply that info. Also that this is for the reciprocating machine must be true.

I had recently a discussion with a electrical motor manufacturer that for obvious reasons have problems to get the motors to survive when connected to this type machines. I guess the only way is to have bearings dimensioned to cope w. The forces that the reciprocating things generate. Babbits type bearings seem to surviving better than ball bearings. IP: fvereb Member posted 02:29 PM If memory serves me correctly, I believe the machine vibration classification number is a number designated by ISO to be compared against a severity level. For example, ISO 10816-1:1995 Annex B (Mechanical Vibration - Evaluation of Machine Vibration by Measurements on Non-Rotating Parts) defines the classification numbers one through four (as they apply to machinery size). I might be waaaay off here, but I'm guessing that you may not have the complete standard or are missing a part there-of.

Be adjusted on the base of experience of the manufacturer or operator. Parts 2 to 7 of the ISO 10816 standard define the limits of vibration severity for various types of machines. Machines that are not listed in these sections are assessed according to. Amendment to Part 1: ISO 10816-1/Amd.1: - zone A/B boundaries 0.71.

Then again, maybe I've been standing too close to the microwave again. Frank Vereb IP: Manuel Martinez Member posted 02:40 PM help, please!!!

Maybe not oficially 'carved in stone' numbers, but something...it is hard to determine the clasification if nobody seems to know. Carson Usb Camera Drivers. I'm the 'expert' here (customer) and my vendor rep. (manufacturer) doesn't even have a phone number or name for tech support, how can we agreed in clasifying.what? It's either vibrating or is not!!!

Our own Diesel guys, who has been in the diesel bussines for a while, 'no eye deer' (no idea) about the right amount of vibes admisible for these 'beasts'. For our big boys, I got a copy of an old memo from the Owners Group.X,Y & Z in foundation and Generator: that's all I have. Thanks, I'm desperate, not for me, but other people need (?)to see numbers 'or something.' Manny IP: OLI Member posted 11:43 AM Diesels are shaky creatures.

The ISO guys write: 'Acceptable severity values will be available if and when circumstances allow'. So what is acceptable is an arrangement between buyer and seller.For electric diesel generators in the size around 1MW pretty hi values are not uncommon like 20mm/s at turbo(s) mounting. I think class 3 to 4 is a reasonable compromise depending on size and operation If you run it as a spare for a nuke 3 min per week, you will have problems anyway. I think I saw some real world figures on locomotive diesels here recently so search on diesels also. Hope you can find something.

IP: Jon Chandler Member posted 12:38 PM I believe the common US Navy standard for diesels is 5 mils pk-pk, measured on the mounting feet. This may serve as a starting point.

Jon Chandler Spintelligent Labs IP: Arne.Lindholm Member posted 11:45 PM Just want to tell you what we use: 4.5 mm/s rms is new and delivery status for all acceptable operating conditions. 11 is limit for still acceptable for long time operation, and limit red = do not exceed is 18. The classes in the ISO /6 is for us a typical vendor submitted list that makes the /6 being of very little use, exactly as Manuel is pointing out. If a vendor wants to write a contract with higher levels than above, we always ask for proof that his machine is made of superior margins and some exotic material that can withstand much higher levels than all the other machines in the world. Machines are still made of steel/metals/lubricants following the laws of physics.